“When can the world refuse plastic?” we ask the co-founder of the Ukrainian company S.Lab a philosophical and dreamlike question.

“Maybe never,” says Julia Bialetska.

The entrepreneur and her husband, Eugene Tomilin, clearly realised the scale of the plastic waste crisis during a trip to Indonesia. There, the local picturesque beaches were covered with mountains of rubbish.

“We analysed the market offers and quickly realised that there was no full-fledged replacement for plastic. For example, alternatives to plastic packaging do not have the necessary characteristics for product manufacturers, such as water resistance and thermal insulation,” explains Julia.

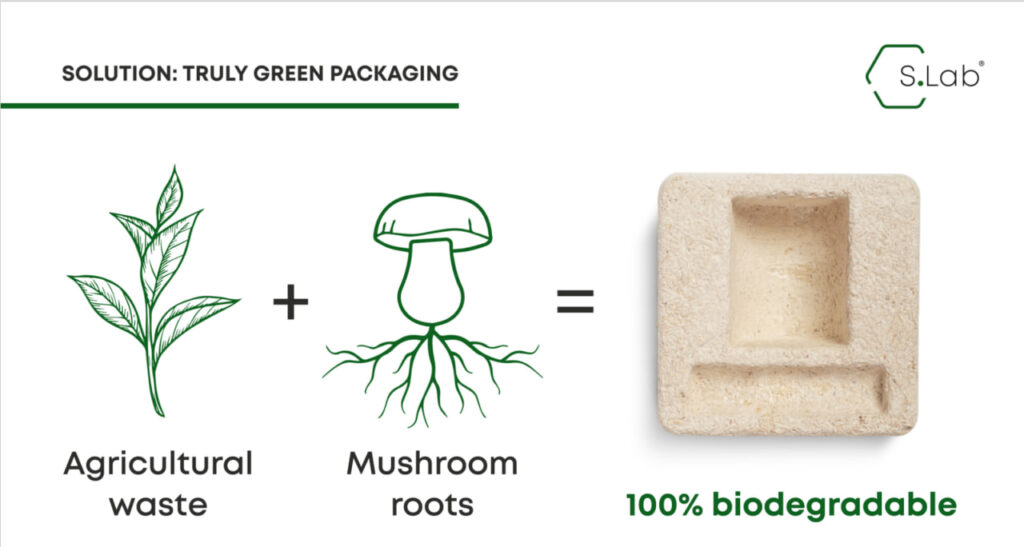

That lack of quality alternatives motivated Julia and Eugene to launch S.Lab in 2021 and create their 100% biodegradable packaging for products made from a combination of two plant-based components — mushroom mycelium and hemp fibres. At the same time, the product has the same features as polystyrene.

The idea turned out to be so in demand in the market that S.Lab is now running out of time to process customer orders. Today, the company, founded in Ukraine, builds production lines in Spain and Japan and intends to change the packaging industry in the European and Asian markets. How? Read on to find out.

The story of S.Lab is a part of the series "The Cream of the Crop of Ukrainian Cleantech". It features 10 cleantech champions who received Climate Innovation Vouchers at a critical stage of their development. Climate Innovation Vouchers is one of the largest grant programs in Ukraine for innovators in green and climate-friendly technologies. It was initiated by the European Bank for Reconstruction and Development and funded by the European Union. Greencubator implements the program in Ukraine.

Packaging with care for nature

As the basis for the future material, Julia Bialetska and Eugene Tomilin chose one of the strongest natural fibres in Ukraine — industrial hemp.

Industrial hemp is a source of natural fibre from which Ukrainians have historically made clothes, shoes, and ship ropes. Moreover, this material is widely used in construction today. Due to its strength, hemp became an ideal base for the couple's product.

The next step was finding a substance that would bond the fibres. An ordinary glue did not work, as it is also synthetic. Instead, the couple found a "natural glue" — mushroom mycelium.

(The S.Lab package consists of only two plant-based ingredients)

The entrepreneurs made prototypes of their products with the Botanical Institute in Kyiv. Here, scientists confirmed the concept's viability and helped grow the first crop of mycelium. Shortly afterwards, the first products made from the new material were produced.

“We started to believe in the project when we sold the first samples,” recalls Julia Bialetska.

Back then, one of S.Lab's first clients was a restaurant that ordered eco-friendly decor for its interior. The couple made vases, chandeliers, and other products for the restaurant. That became the startup's starting point.

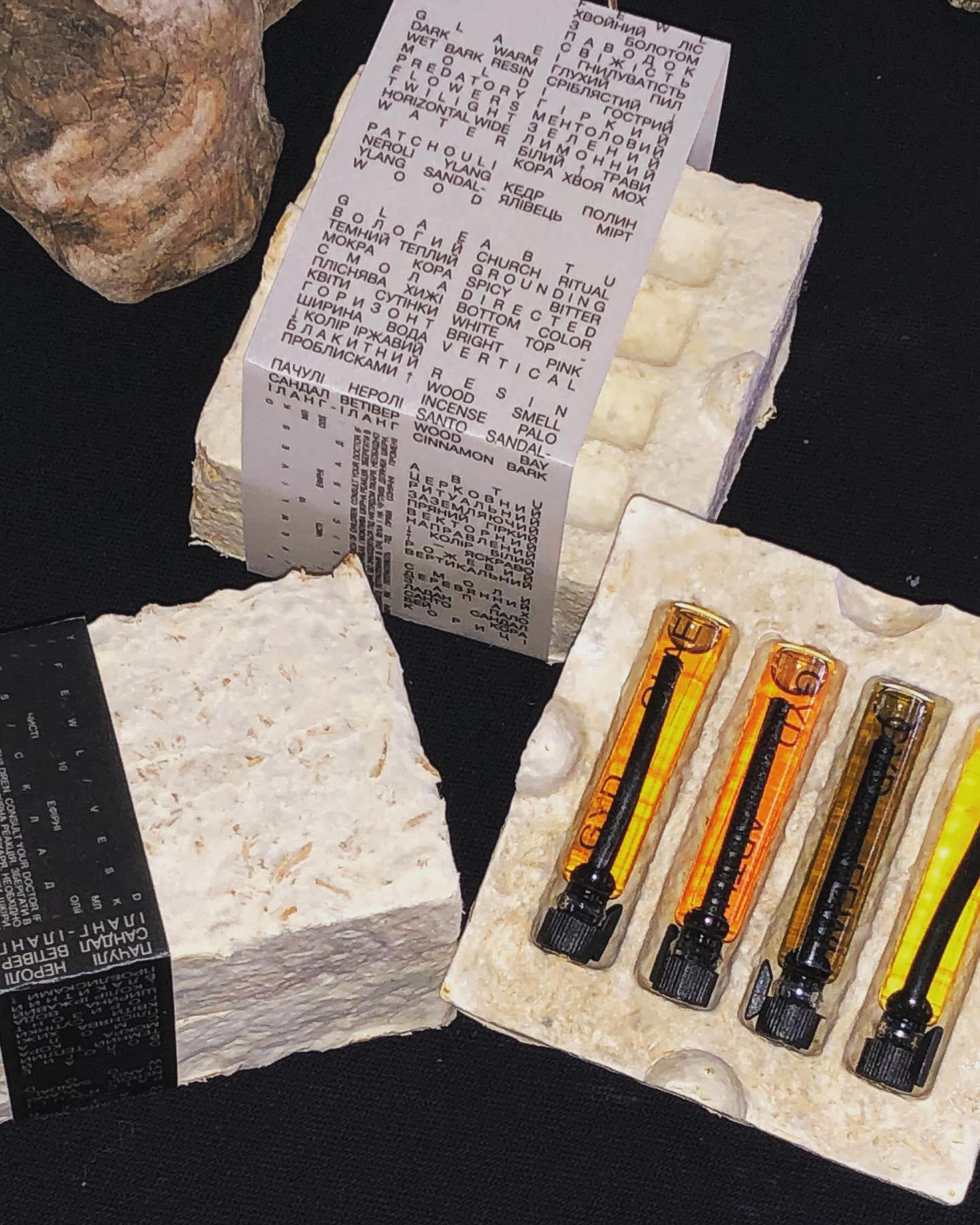

(Decorative products from mushroom mycelium and industrial hemp)

People started to talk about the unusual business and tag the company on social media. At the same time, the S.Lab team tried to be in the public eye: they spoke at various startup conferences and took part in acceleration programmes. And it paid off. Brands kept contacting the young company and offering cooperation. Among the first significant collaborations was a project with L'Oreal, the world's largest cosmetics manufacturer.

(S.Lab collaborations with brands)

S.Lab currently focuses on the packaging market, estimated to be €1 trillion annually. Since the coronavirus pandemic, delivery services have grown significantly in the global market, and as a result, the need for packaging for goods and products has also increased.

Technology evolution and recognition

At the start of February 2022, S.Lab set up manual packaging production in Kyiv. Even though the startup had a lot of orders from customers, due to its scale, the company could only produce a limited amount of products.

"It was clear to us that if we wanted to succeed, we needed to build a production line, upgrade our technology and invest in innovation. So, we began to look for additional funding and applied for grants," Julia comments.

In December 2022, S.Lab became one of the winners of the EBRD and the EU's Climate Innovation Vouchers grant programme. Ukrainian NGO Greencubator has been implementing this grant scheme in Ukraine since 2017. Thanks to the project, the company received funding for the technology development of its future production line and to patent the invention.

(Julia Bialetska at the Climate Innovation Vouchers award ceremony with Greencubator co-founder Roman Zinchenko and project manager Olga Zubchyk)

The support of the European Bank for Reconstruction and Development and the European Union has also given S.Lab a boost in its brand image. International recognition paved the way for the startup to receive numerous other investments and grants.

In March 2022, the company received its first investment from the Startup Wise Guys accelerator, and within a year, the total investment in S.Lab reached 400 thousand euros. Then, S.Lab received one award after another. For instance, the Ukrainian Startup Fund recognised the company as the Startup of the Year. At the end of 2023, S.Lab was among the TOP 10 startups at the international technology conference WEB Summit out of 3,000 applicants.

"Despite many international awards, the victory at the Ukrainian tech conference IT Arena is dearest to my heart because it was in Ukraine. Moreover, we closed an investment of $210 thousand, which was announced right on stage. This is a precedent. Ukrainian investors have finally started investing in our startups," says the co-founder of S.Lab.

All the grants and investments allowed the companies to reach a new scale of work and start building their first production line in Spain.

(Julia Bialetska at the Ukrainian Startup Fund's award ceremony)

S.Lab technology for every production

The decision to build the production line in Spain was not an easy one for the team. Due to Russia's full-scale invasion in February 2022, S.Lab had to relocate its business abroad.

Due to this forced change, the company had to modify the product slightly. The main suppliers of industrial hemp remained in Ukraine, and it would have been unprofitable to deliver raw materials to Spain. So, the team has found another solution. Considering that the technology allows almost any agricultural waste to be used, S.Lab decided to work with local farmers. As a result, industrial hemp was replaced in Spain with a mix of bast crops.

"The production line manufactures packaging on an industrial and commercial scale. In the beginning, we will produce 50,000 packaging units per month. Then we will improve just a few production units and be able to produce 100,000 units in just one month. By the end of 2024, we plan to expand to half a million packages per month," Julia Bialetska shares her plans.

However, S.Lab already understands that they can't meet the market demand for eco-packaging on their own, no matter how much they increase production. So, the company decided to put the same automated production line into a 40-foot container, like the ones used to transport goods by sea. Thus, the company won't sell eco-packaging but the technology to worldwide manufacturers.

"Our customers can install such containers in their production facilities and produce eco-friendly packaging for themselves. This solves many logistical problems because nowadays, packaging materials are mostly made elsewhere and transported to the production site," says Julia.

(The S.Lab team)

This decentralisation of small-scale production is an innovation in the field of eco-friendly packaging from S.Lab. This is a future vision that potentially solves the problem of rural decline due to lack of work. For example, such containers can be installed in villages to produce eco-friendly products for sale using raw materials from local farmers.

"Our main task is to make the technology as automated as possible. So, the customer will only need to load the raw materials on one side and receive the finished packaging on the other. Inside, everything will work with the help of robots, sensors and detectors. All data will be collected and sent to the control system.'"

According to S.Lab's plan, customers would not need to hire a full-time engineering department to maintain their equipment. One person will be enough to load the raw materials and check all the system indicators. The company will take care of staff training and technical support. In particular, the company is ready to supply prepared raw materials to the manufacturer where it is required.

Fierce demand without competitors

While it is typically challenging for a company to find customers, S.Lab even stopped accepting orders while working on the production line due to too high demand. Meanwhile, the eco-packaging market is growing the fastest in the segment - by 15-20% annually, twice as fast as the industry. Despite this, S.Lab's competitors in the global market can be counted on one hand.

"We can divide our competitors into two large groups. The first is foam packaging, which we want to replace with our plant-based alternative. However, they can hardly be called competitors because regulators in different countries are forcing them to stop using such packaging and raising taxes. So we clearly understand that in 5 years, it will be more expensive to use polystyrene than its eco-friendly alternative.

The second group of competitors is eco-packaging manufacturers. For example, the American startup Ecovative also mixes mushroom mycelium with sawdust. They have been on the market for eight years, have many different products, and have raised about 60 million in investment since last year. However, they are more like-minded people than competitors. We look at them as potential partners in the future," explains S.Lab co-founder Julia Bialetska.

The advantage of S.Lab over its competitors is that from the beginning, the company has invested in efficient and powerful technology that can be deployed anywhere.

"Growing demand for eco-friendly packaging gives us the strength to move forward. Consumers want to interact with environmentally friendly materials, and responsible businesses must respond to this demand. We work hard to ensure that our alternative to foamed plastic is the first thing that pops into consumers' minds and that our clients know that we are a reliable partner on their path to social responsibility," says Julia.

Eco-friendly packaging is not only in demand in the Spanish market. The startup is already building a production line in Japan to enter Asian markets, and among other European countries, the team is considering Austria and Ukraine in the first place.

The demand for 100% biodegradable material is high in almost all areas of retail - electronics, beauty, fashion, healthcare, and pharmaceuticals. It is essential that the proposed packaging does not crumble in three days and performs the same functions as ordinary styrofoam or plastic. Only then, Julia Bialetska believes, companies worldwide will be ready to switch to an environmentally friendly alternative, even despite the higher cost of the product. The S.Lab team brings this transition to plastic-free production and a garbage-free ocean closer daily.

ABOUT THE PROJECT

«The Cream of the Crop of Ukrainian Cleantech» is a series of stories about 10 Ukrainian companies that received the Climate Innovation Vouchers grant at a key stage of their development. They've risen to prominence in Ukraine's cleantech sector in a short span. Climate Innovation Vouchers is one of the largest grant programs in Ukraine for innovators in green and climate-friendly technologies. It was initiated by the European Bank for Reconstruction and Development and funded by the European Union. NGO Greencubator implements the program in Ukraine.