There is a floating "island" of garbage in the Pacific Ocean – the Great Pacific Garbage Patch. The area of this whirlpool of plastic and fishing gear is larger than the entire area of Ukraine. It would seem far-fetched if the toxic microplastics formed there and throughout the world's oceans were not detected in human lungs and blood.

The fact is that plastic does not decompose; it only breaks down and travels further with the water we drink, the seafood we eat, and the air we breathe. In addition to its dramatic effects on our health, it kills millions of marine animals every year who mistakenly consume it. Almost 100% of human-made plastic still exists, and every minute, a truckload of plastic waste enters the ocean in various ways…

How can the problem of collecting and recycling plastic, which is extremely painful and urgent for our planet, be solved? The Good Plastic Company has invented its way to curb the toxic influx of plastic into nature, turning it into elements of exquisite interiors with a long service life. Please read about this exciting metamorphosis in our new story.

The story of The Good Plastic Company is a part of the series "The Cream of the Crop of Ukrainian Cleantech". It features 10 cleantech champions who received Climate Innovation Vouchers at a critical stage of their development. Climate Innovation Vouchers is one of the largest grant programs in Ukraine for innovators in green and climate-friendly technologies. It was initiated by the European Bank for Reconstruction and Development and funded by the European Union. Greencubator implements the program in Ukraine.

An Innovative Idea From the Seaside

William Chizhovsky, the future founder of The Good Plastic Company, received a brilliant economic education at Harvard University. He took a parallel course with Mark Zuckerberg and once attended his lecture on intention. Then, Mark advised him to create a business that would make the world a better place.

A few years later, during a trip to the Mediterranean countries, William's wife drew his attention to the garbage in the azure water: “Look, how much plastic is in the sea! If you could do something about it…”. With it, the student's intention began to take shape.

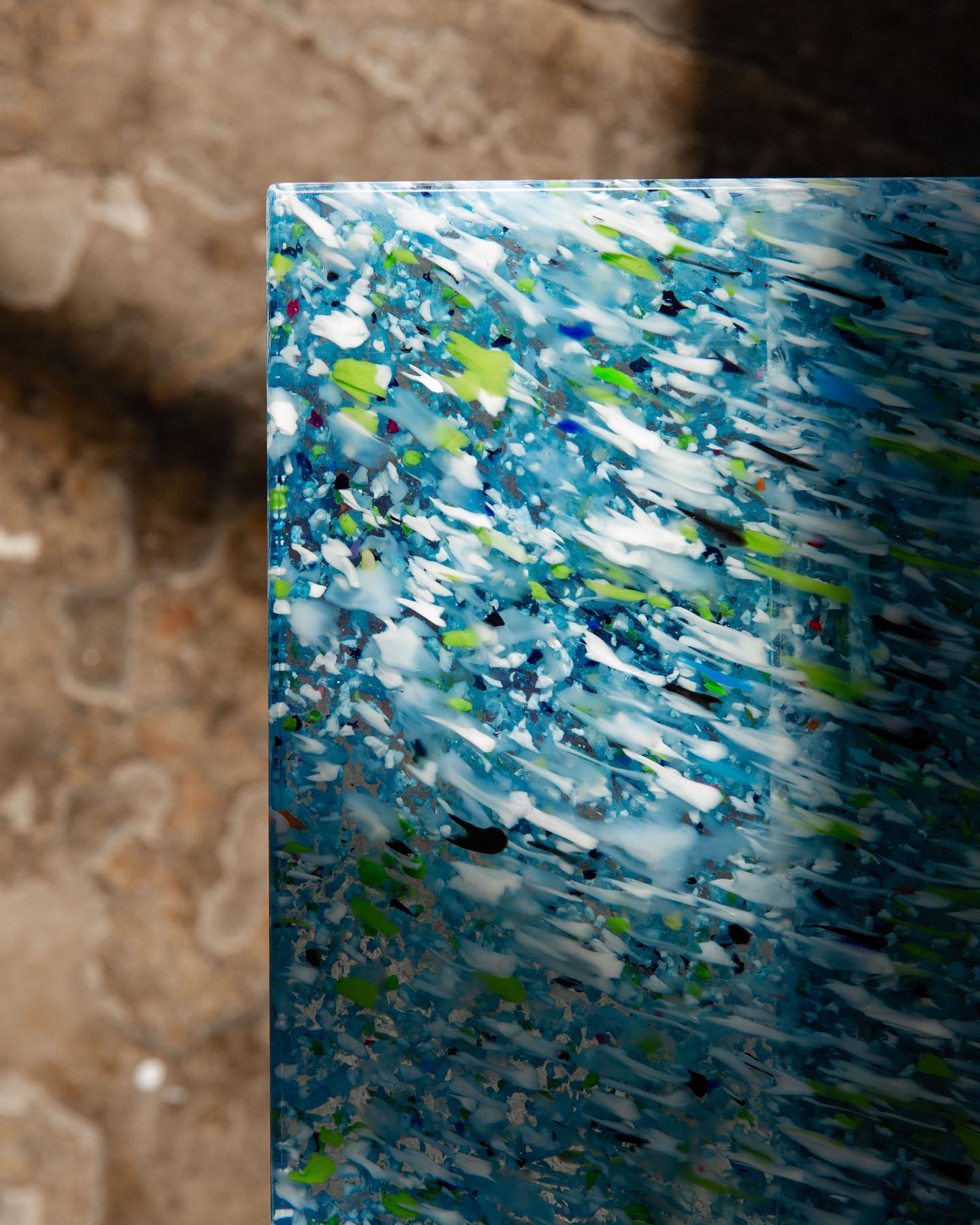

William has developed a unique technology for transforming plastic waste into a beautiful, strong, and sustainable surface and packaging material. He created The Good Plastic Company and began producing furniture, exhibition stands and designer decorative panels entirely from recycled plastic in various colors and shapes. The company declared that plastic is not trash, and that it will make its products a standard type of material, on par with primary plastic or wood.

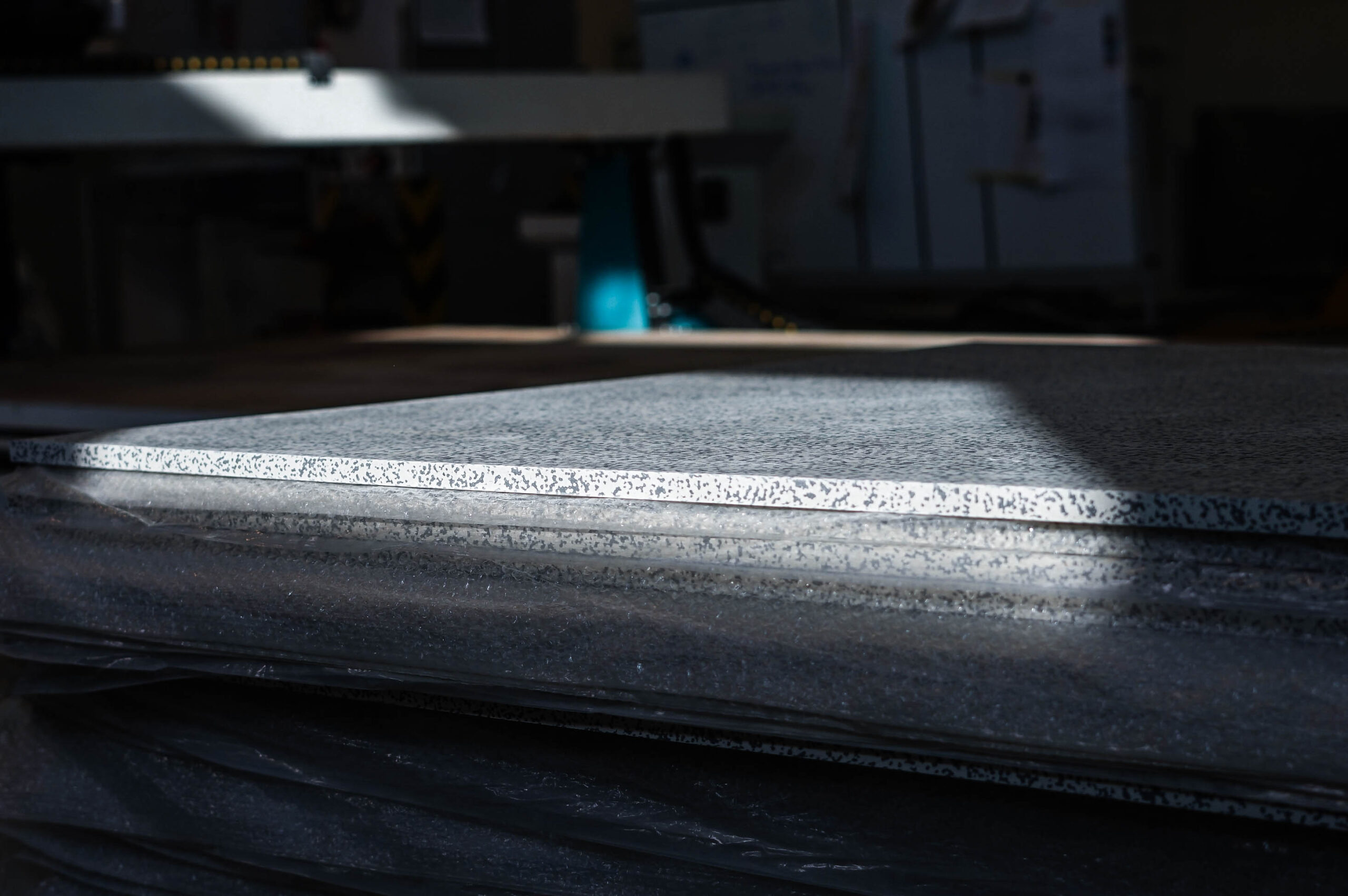

The clients who want to demonstrate their contribution to sustainable development and, simultaneously, are looking for creative solutions to design their stores and offices have appreciated this idea. The Good Plastic Company became the first in the world to be able to produce large 1.4 x 2.8 m slabs from recycled plastic (PS) in industrial volumes. By implementing their idea, they managed to leave already extracted resources in the industrial chain and, at the same time, create new, unique products. They gave plastic a second chance to serve long and brightly.

(Transformation of secondary plastic into original interior design using the technology of The Good Plastic Company)

Certification and Trademark

If it was enough five years ago to declare that the material is sustainable, which attracted environmentally conscious customers, now more and more "greenwashing" has appeared – the declared sustainability of various manufacturers has ceased to correspond to reality. To convince customers of the sustainability of their materials, The Good Plastic Company felt the need for the most important certificate in their industry - Cradle to Cradle Certified Product Standard. This complex certification should confirm that they produce the material from entirely recycled materials, that reduce CO₂ emissions, and its properties meet European standards.

In 2021, The Good Plastic Company won the EBRD grant Climate Innovation Vouchers, financed by the EU and implemented in Ukraine by the NGO Greencubator. The company became another Ukrainian (or rather, Ukrainian-Dutch-British) climate champion and invested part of the grant funds precisely in the critical development step – the desired certification. It lasted more than a year.

(COO of the company Victoria Sedova with colleagues and an award from Climate Innovation Vouchers)

"Those who certified us were at our factories. They checked that everything is as we claim, that it is exactly recycled plastic, – says William Chizhovsky. – They checked our suppliers and did a lot of laboratory tests and research. Today, we are the only company in our industry with this certification. It makes us very different from other companies. With this, we declare that we are transparent and truly a "green" company. This certification helps us to work better with customers, with large global companies, who value knowing that their suppliers are making truly sustainable material."

Cradle to Cradle Certified opened the door to cooperation with companies where certification was mandatory, such as airports and shopping centers. It was essential for Europe and Great Britain, where businesses work only with tested and certified materials. Thanks to the certification, the company has moved to the top league.

The Good Plastic Company used half of the grant amount to register the Polygood® trademark and apply for a patent for its innovative solutions. The company has already received trademark registration in the EU, Australia, Great Britain, and, recently, in America.

Production of Beauty From Waste

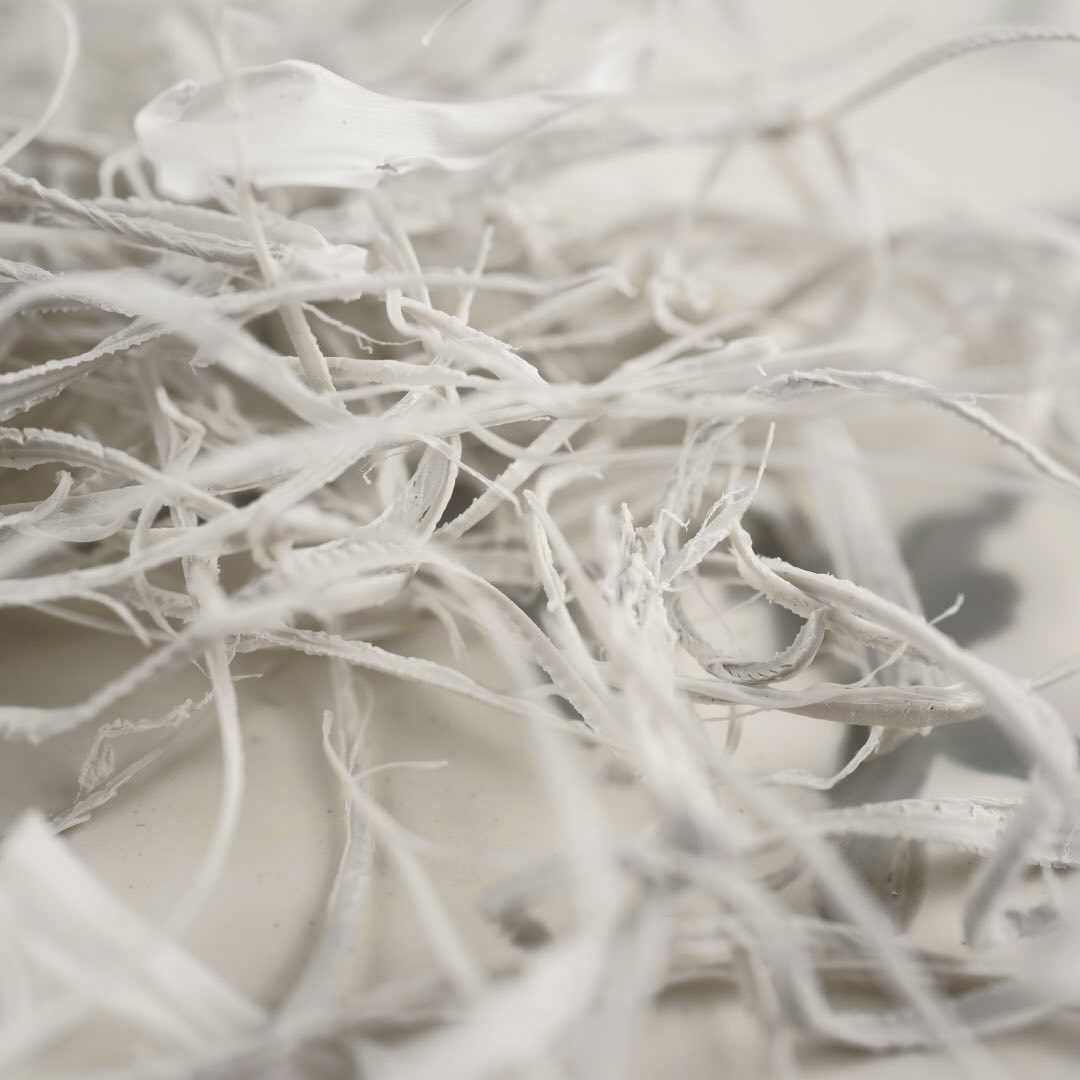

The Good Plastic Company's technological process resembles a bartender mixing cocktails or a chef in an experimental kitchen. They press these mixtures in special "toasters" for plastic into facing slabs with an intricate ornament. Former refrigerators, computer mice, keyboards, plastic furniture and filters are becoming interior items, which top designers of shops and office spaces follow. Ocean plastic collected in Hawaii (wildly smelly) becomes elegant catwalks for world-famous brands and couturiers of high fashion. Recycled disposable dishes turn into panels and furniture for elite spaces and design weeks in Milan or London. Even the shavings return to production and become fragments of products, which introduces unexpected solutions.

(William Chyzhovsky at a factory in the Netherlands and the surface materials produced there with an already recognizable ornament)

Polygood®'s revolutionary material is causing hype in the design world. Some of the leading media outlets in the industry, where designers learn about the latest and most innovative developments in their field, recognize it. Publications about the environmentally friendly surface material Polygood® appear in Material Futures and prestigious Interior Design magazines.

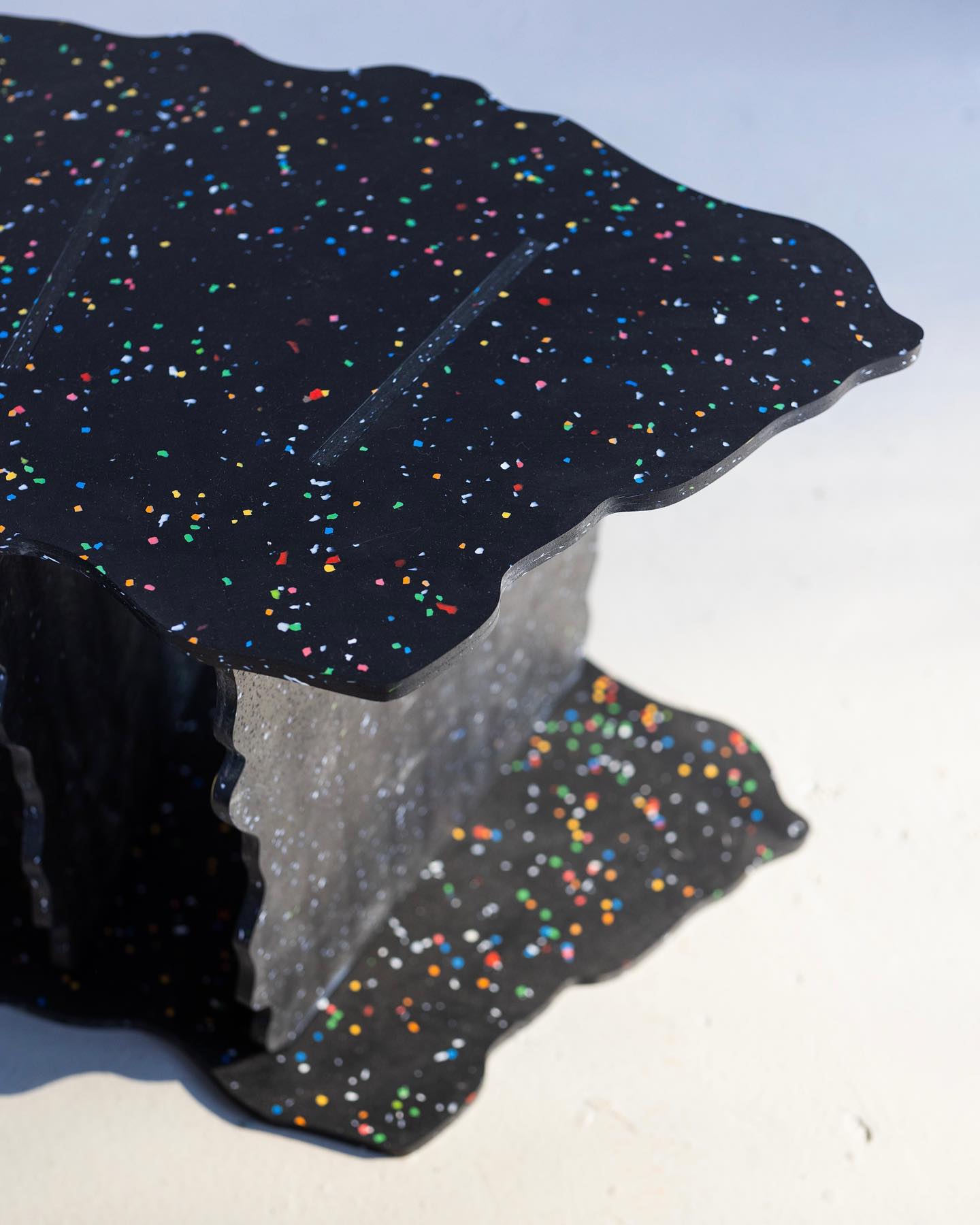

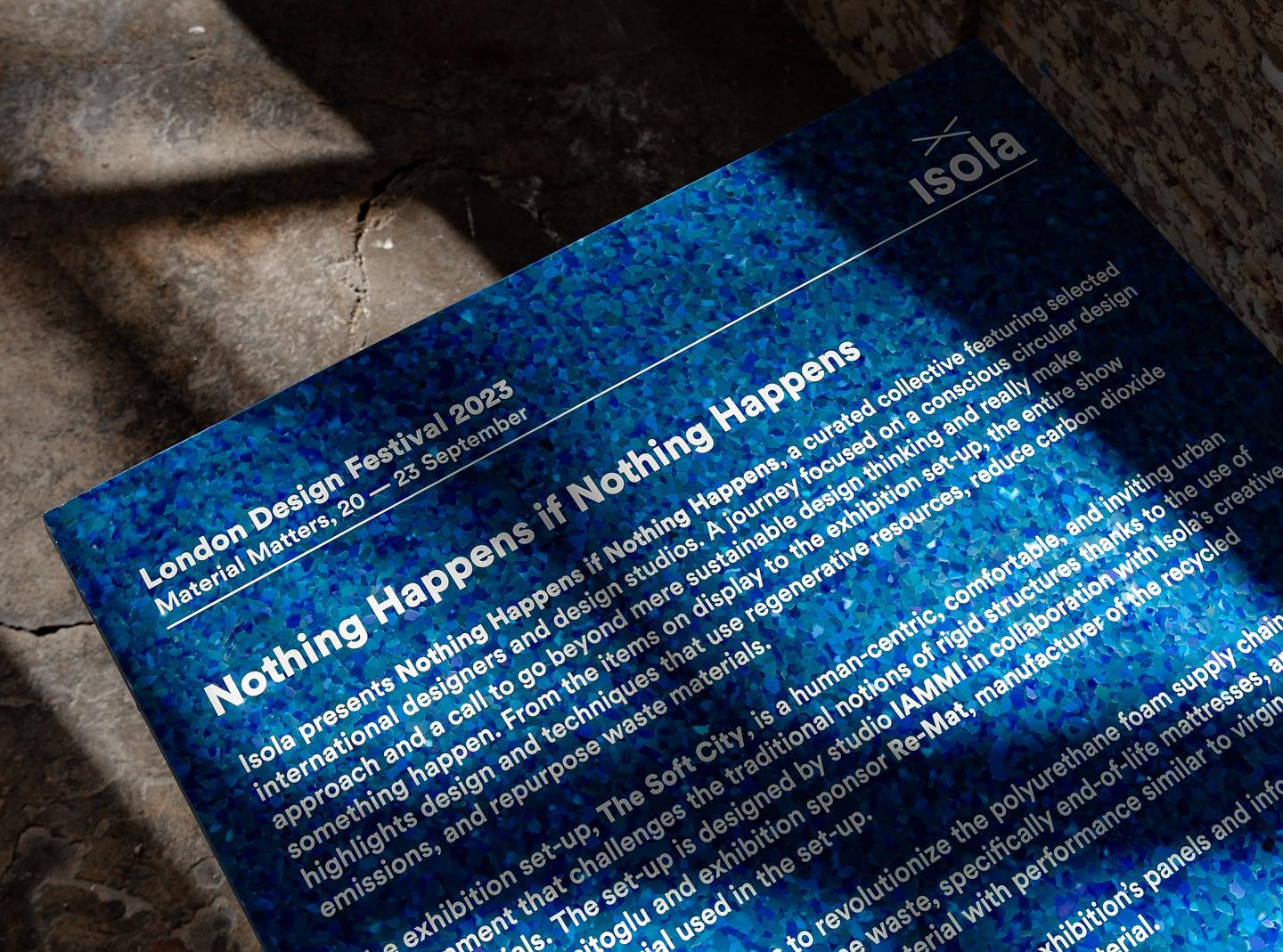

(The Nothing Happens If Nothing Happens exhibition at the London Design Festival 2023, where the Polygood® pattern accurately conveys the elegance and sophistication of real marble)

Podiums and tables made of Polygood® played a vital role in designing the 11th Architizer A+Awards gala, one of the most spectacular architecture and design events held in the heart of Paris. The conscious transition to sustainable materials is still challenging in this industry, but Polygood® panels fully meet its strict standards.

(Architizer A+Awards stage decorated with Polygood® products and the review in the famous Material Futures)

Factories and Investments

The Good Plastic Company's production facilities were initially entirely based in the Netherlands. In 2018, William chose the country that ranks first worldwide for material reuse and waste management to build his first factory in Almere, near Amsterdam.

In 2021, the company moved most of its production to Ukraine – to the "Bila Tserkva" industrial park in the Kyiv region, to a 2,500-square-meter factory. Plastic processed in Bila Tserkva began to be sent all over the globe – to customers in Tokyo, New York, California, and Europe.

In the early days of the full-scale invasion, company workers came to the factory to stick together. Despite the missile attacks, production did not stop. However, in March 2022, the company managed to relocate production and the team to Chernivtsi, and already in the first quarter of 2023, the factory was working at maximum production.

(The Good Plastic Company factory in Chernivtsi)

During the relocation period, The Good Plastic Company attracted investments from the Ukrainian fund Vesna Capital, created by marketer Andrii Fedoriv and the founders of Nova Poshta, Vyacheslav Klymov and Volodymyr Popereshniuk. Investors helped William draw up a roadmap for the company's development for the next three years. So, today, The Good Plastic Company's two factories in the Netherlands and Ukraine can produce more than 1,000 tons of recycled plastic panels per year, meeting the demand in this sector.

At the same time, the company participates in projects for Ukraine's restoration, such as the construction of playgrounds in de-occupied territories. The first such playgrounds will soon appear in the village of Makariv in the Kyiv region.

Conscious Customers Promote Sustainability

The shelves and racks at the Lush store in Bern, Switzerland, are made from 400kg of Polygood® plastic from recycled consumer electronics. 270 Nike stores worldwide have used shoe collection boxes also made from Polygood®. For Samsung stores in Finland, France, Germany, and Italy, the company made tables to demonstrate models of the latest Galaxy series, saving 3,500 kg of polystyrene (PS) from entering the ocean and our bodies.

(Polygood® racks, boxes and shelves in Samsung, Nike and Lush stores)

Adidas, Karl Lagerfeld, McDonald's, and Ikea use Polygood® material to decorate shops, showrooms, and restaurants. The Good Plastic Company can show its industrial scale thanks to cooperation with such giants. Why do big brands choose such niche materials? They are durable, can be integrated into any space in large quantities, and are easily recycled. Using Polygood®, brands demonstrate their commitment to sustainable development and attract customers who share their values.

But it's not just big brands that contribute, but small businesses, too. For example, the L'Emile bookstore or the Morning co-working space in Paris, with the help of The Good Plastic Company, repurposed 1,518 kg of recycled plastic and thus reduced its environmental footprint.

New Markets in Different Parts of the World

In 2023, the company's sales volume increased, and the team grew to 60 people. The Good Plastic Company has raised a second round of angel investment from private investors and has grown in value. William Chyzhovskyi tells:

"We were able to launch work with several large distributors in just one year. In March 2023, we had a distributor in Great Britain, CDUK – one of the largest companies selling surface materials. We have a distributor, Danube Middle East, a huge company with a turnover of several billions. It works in 6 countries in the Middle East, and there is a construction boom. Accordingly, we expect that there will be a high demand for our material. In addition, the tables at the United Nations Conference on Climate Change COP28, held in Dubai, were made of Polygood®. Thus, we are strengthening our position in Europe, where we were, but now we have entered the Middle East, where we are already leaders in the market of ecological materials."

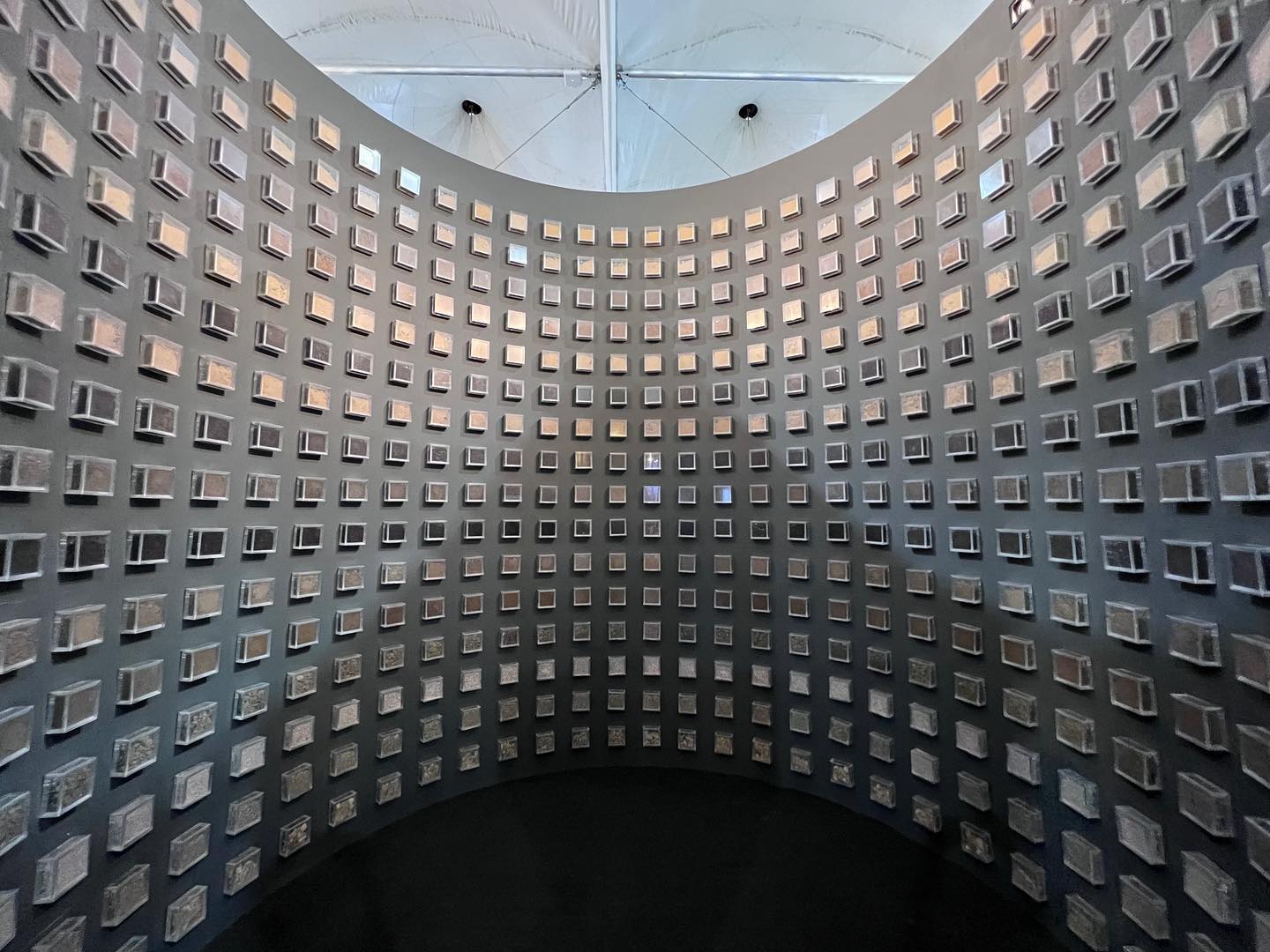

(An installation in the shape of a shell funnel, located in the center of the Ukrainian pavilion at COP27 in Sharm el-Sheikh. Inside the installation are more than 500 cubes created from Polygood®, with 16 types of Ukrainian soil, as a reminder of the enormous potential of Ukraine and its importance to global food stability)

In late 2023, the company entered India with a leading distributor, Future of Surfaces, specializing in modern eco-friendly products and services with a wide range of applications. At the beginning of 2024, the company got a deal with a large distributor in Scandinavia. And on January 3, The Good Plastic opened an office in the center of New York. This crucial step will allow them to serve customers throughout North America better. On the eve of the opening of the office, from a business trip to the USA, William shared his plans:

"This is a huge event for us, the biggest in recent years. It's a huge market, and we already have a lot of inquiries. We will work in America by ourselves, without distributors. We expect this to be a major game changer for the company. Therefore, our task for 2024 is to develop business in America and turn it into a huge sales market. As soon as we can collect some income in America, we will start building another third factory. Optimistically, it will be the end of 2024."

(A fabulous recreation area in the center of The Circular Village as part of the Isola Design Festival & Milan Design Week 2023, made from 100% recycled Polygood® plastic)

The bigger William Chyzhovsky's company becomes, the less abandoned plastic can end up in the world's oceans. Thanks to him, not only fish in California's markets will contain less plastic, but also haarder and capelin in Odesa's markets. It will attract more buyers to showrooms' bright showcases and promote values capable of changing patterns of human behavior (after all, it is clean not only where they clean but also where they do not litter).

Today, The Good Plastic Company creates new game rules in the market, harmoniously combining aesthetics and sustainability and changing the world for the better.

ABOUT THE PROJECT

«The Cream of the Crop of Ukrainian Cleantech» is a series of stories about 10 Ukrainian companies that received the Climate Innovation Vouchers grant at a key stage of their development. They've risen to prominence in Ukraine's cleantech sector in a short span. Climate Innovation Vouchers is one of the largest grant programs in Ukraine for innovators in green and climate-friendly technologies. It was initiated by the European Bank for Reconstruction and Development and funded by the European Union. NGO Greencubator implements the program in Ukraine.